Position:Home > Working Glass Container

Description

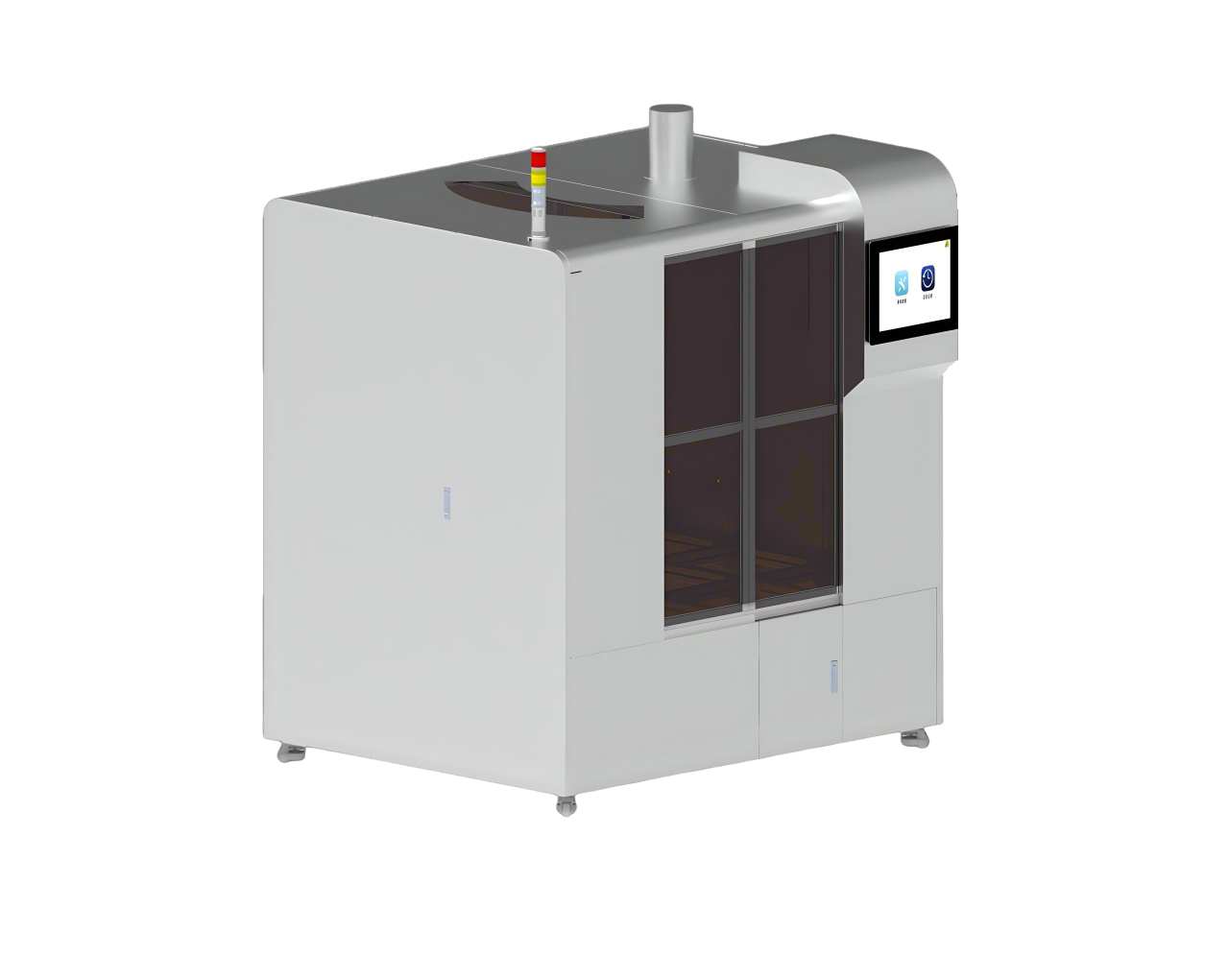

Volumetric bottles, cups, cylinders, pipettes, burettes are common glass gauges in the production and experiment process. In order to ensure the accuracy and reliability of the measuring value, it is necessary to calibrate each glass measuring device, which is a daily measuring work with a large amount and a wide range. When measuring institutions check glass gauges, there are often many quantities, low charges, time consuming, fragile gauges and so on. The commonly used automatic calibration device of glass measuring instrument, based on computer image processing algorithm, adopts automation and intelligent application technology to realize the automatic calibration of common glass measuring instrument: automatic completion of liquid intake, liquid discharge, weighing, cleaning, automatic data recording, automatic report generation. When calibrating, each station can place different types and different models of glass gauges, the calibration process is independent of each other, can be asynchronous calibration, do not affect each other.

Main parameters - Number of stations: typical station number 20, can be customized - Scales: 3 sets, covering all weighing ranges of the specification - Marking and level identification: high resolution image sensor

- Full automatic: automatically complete calibration, automatically record data, automatically generate reports - Safety: Safety protection is carried out on the glass gauge during lifting and rotating of the calibration device to avoid the fragility of the glass gauge - High return: save valuable human resources, for high output value testing work, greatly improve the economic benefits of the measuring mechanism

|

ENGLISH

ENGLISH 中文

中文