Description

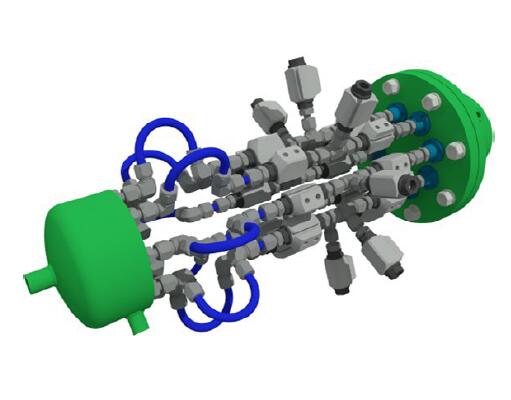

The series of SMF® nozzle test benches has been specifically designed for calibration with gases. Up to 8 sonic nozzles can be combined, depending on customer requirements. The different circuits resulting therefrom allow a flow generation of 28 = 256 different flow rates. A precise flow can be adjusted in a very short period of time (about 500 ms). The register is made of drum configuration and equipped with appropriate sensors (temperature, pressure and humidity) for density determination. A calibration assembly provides an atmospheric suction through the test item and the nozzle drum. A vacuum pump, or the connection to house vacuum power, ensures the generation of the necessary sonic pressure ratio downstream. Alternatively, operation can be carried out with overpressure. The system is controlled by a PC with precise data acquisition hardware and control software in LabVIEW.

Technical data

Measurement parameters Volume flow : 0.0025...100 m3/h

Medium : atm. air, compressed air, natural gas, hydrogen, other gases

Dimensions (D x W x H) : 800 x 1600 x 2000 (mm)

Weight approx.: 500 kg

Measurement parameters

Absolute pressure – ambient P amb

Temperature - ambient T amb

Absolute pressure – in front of nozzles P NOZZLE UP

Temperature – in front of nozzles T NOZZLE

rel. humidity - in front of nozzles rH NOZZLE

Absolute pressure – downstream from nozzle: P NOZZLE DOWN

Advantages

Compact design

Integrated inlet section

Highest accuracy – up to 0.12%

Approved by the PTB as a calibration standard

Representation of the volume flow or mass flow

Flexible nozzle adjustment per customer requirements

Gas meter calibration up to G 65

Excellent long-term stability - recalibration period up to 10 years for sonic nozzles