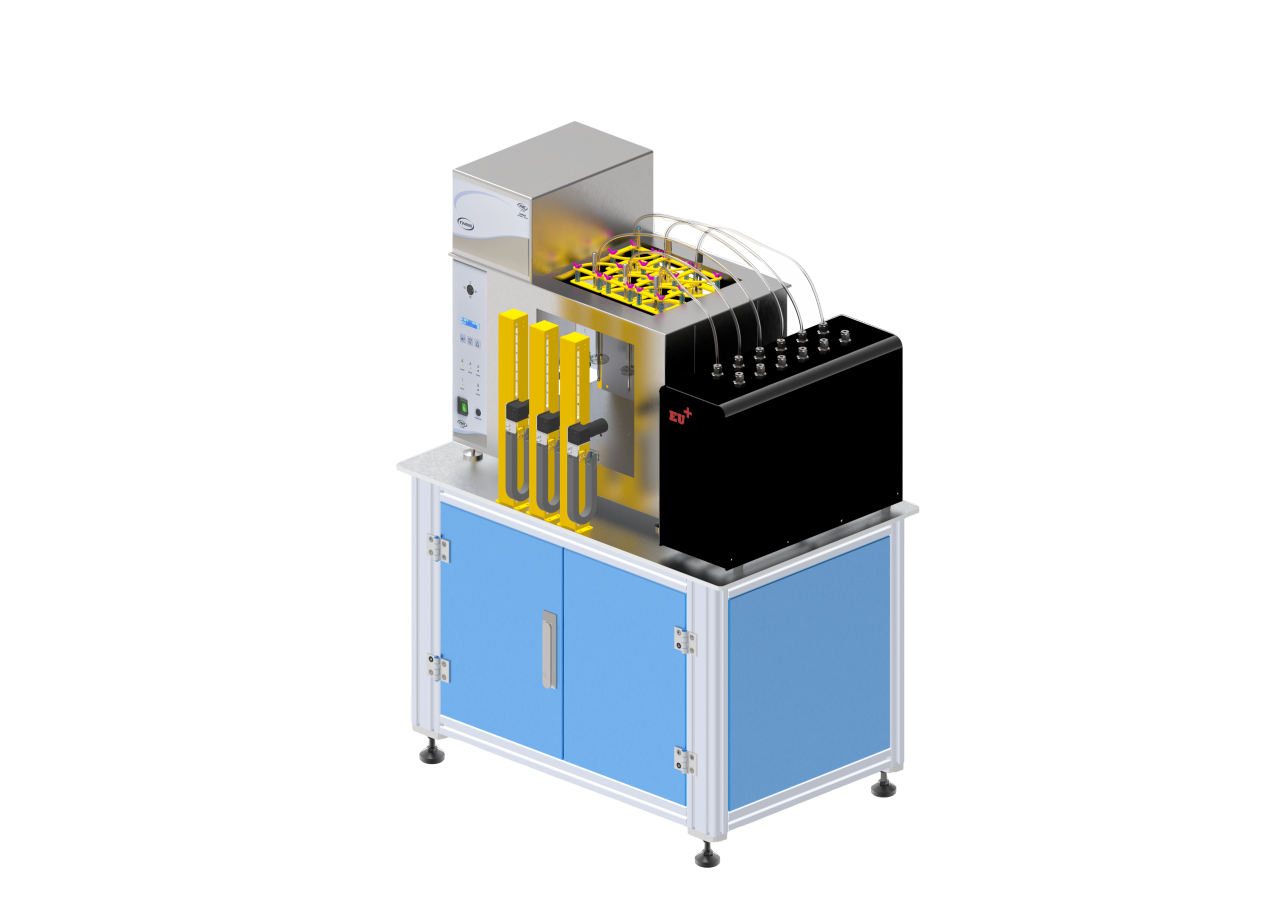

Capillary Viscometer Automatic Calibrator

The viscometer

must be calibrated before leaving the factory or putting into use for the first

time to ensure that the performance indicators of the instrument meet the

requirements of the national metrology verification regulations; At the same

time, the viscometer in use needs to be periodically verified, and if necessary

(the instrument is used frequently or in a qualified critical state),

intermediate self-inspection should be carried out to determine its metrology

performance is qualified, and the coefficient error is within the allowable

range, otherwise accurate data cannot be obtained. In the calibration and

verification of viscosity timing, the measuring mechanism often exists a large

number, low charge, time consuming and other situations.

According to the

actual situation in the field of fluid viscometer measurement, EUCA Technology

Co., Ltd. has developed an automatic calibration device for VAC capillary

viscometer. It is based on computer image processing algorithm and adopts

automatic and intelligent application technology to realize automatic

calibration of capillary viscometer: automatic suction, automatic recognition

and automatic timing. That is to liberate manpower and save resources.

Calibration viscometers include Ubbelohde Viscometer,Pinkevitch Viscometer, Cannon-Fenske Routine Viscometer ,Cannon-Fenske Opaque Viscometer.

Product features

and advantages

◆ When

calibrating, different types and models of capillary viscometers can be placed

at each station. The calibration process is independent of each other, and can

be calibrated asynchronously without affecting each other

◆ VAC

capillary viscometer automatic calibration device is composed of precision

transparent constant temperature bath, high resolution image sensor, precision

lifting table, pressure control system, motion control system and algorithm

processing system. The precision transparent constant temperature bath provides

a stable and uniform temperature field for the viscometer to be tested, the

temperature fluctuation does not exceed ±0.01° C/h, and the temperature field uniformity does not exceed ±0.02 ° C.

◆ The

high-resolution image sensor is placed outside the precision transparent

constant temperature bath window, driven by the precision lifting platform

precisely controlled by the motion control system. The function of the image

sensor is to quickly and accurately identify the inspected engraving line, and

accurately calculate the time of the marking oil passing through the inspected

engraving line. Based on a unique recognition algorithm, the VAC automatic

calibration device can check all four categories of viscometers specified in

the specification, significantly improving the reliability of identification

and timing accuracy

◆ The

pressure control system will vacuum the standard oil inside the viscometer to

the appropriate position, and then make the standard oil flow under atmospheric

pressure

Since the

corresponding pressure control unit, image sensor, lifting platform, motion

control unit, etc. of each station constitute a self-proclaimed system of

calibration system, each station is independent of each other and does not

affect each other, so as to truly realize asynchronous calibration and improve

the flexibility and efficiency of calibration.

Product value

☆ Efficiency: Each station asynchronous calibration, do not affect each other

☆ Flexibility: Different types of viscometers can be placed at each station

☆ Practicability: All four categories of viscometers can be checked according to

the regulations

☆ Reliability: Unique image processing algorithm, accurate and reliable

identification timing

☆ Economy:

The user can choose 1~6 stations, and the subsequent stations can be added

☆ High

return: The viscosity project enhances the user's viscosity, and the output

value has a high comprehensive return

The device will be

applied to an inspection and certification institute.

|